A Look at the Engineering Behind Precision

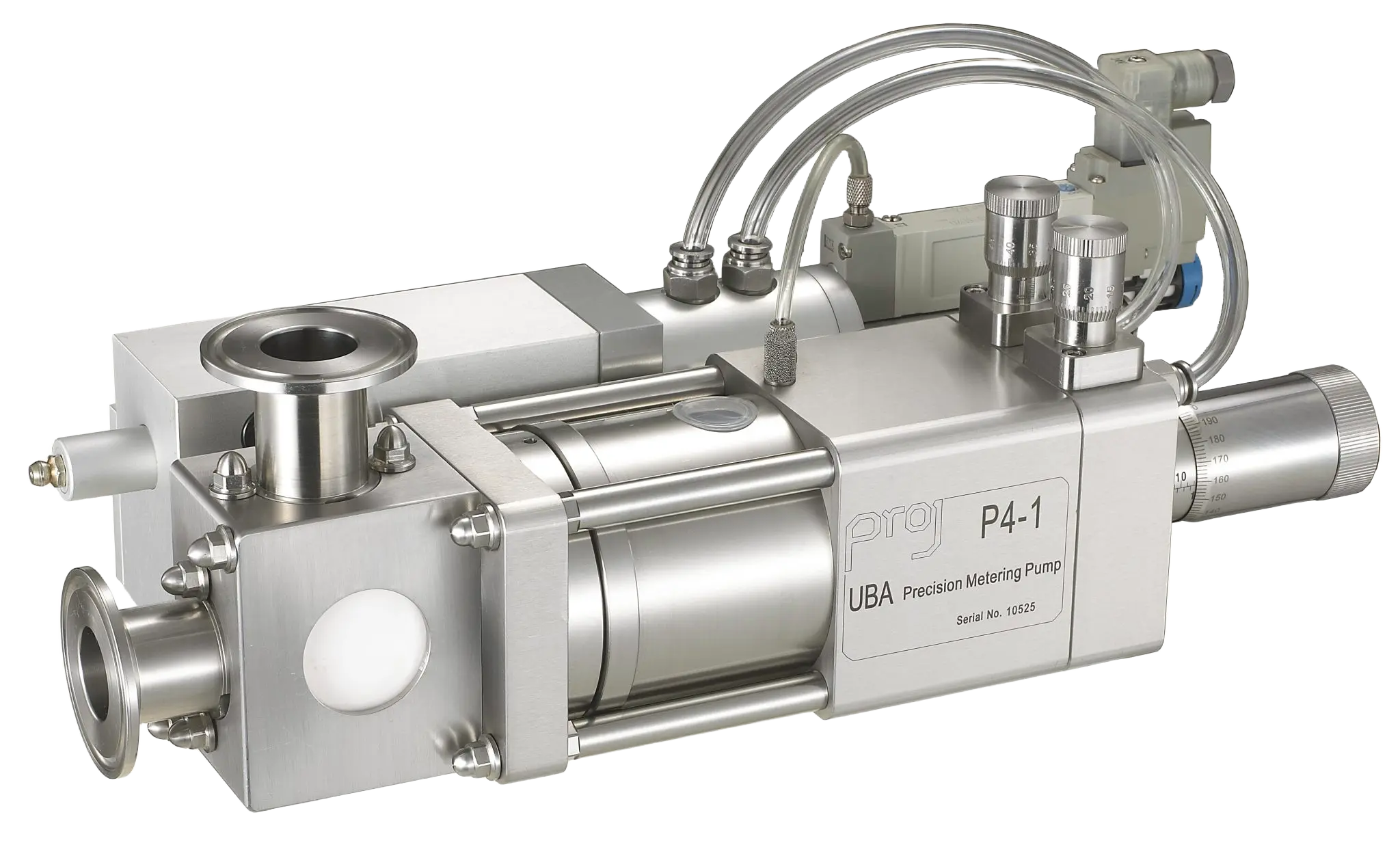

Precision in liquid filling isn’t just about hitting a target – it’s about hitting it every time. Whether you’re working with delicate pharmaceuticals or thick cosmetic creams, consistency is what keeps quality high and waste low. That’s why we trust UBA metering pumps: they’re engineered to deliver the same volume, stroke after stroke, no matter the fluid.

So what’s behind that level of reliability? Let’s break it down.

🎯 Positive Displacement: Built for Consistency

UBA pumps operate on a positive displacement principle. That means every stroke moves a fixed volume of fluid – no guesswork based on pressure or flow rate. You control the stroke length and speed, and the pump delivers exactly what you set. It’s a simple, predictable system that’s ideal when accuracy is non-negotiable.

⚙️ Precision Parts, Precision Results

Inside every UBA pump, the components are machined to tight tolerances. That kind of detail matters. It ensures:

– Minimal wear over time

– Fewer adjustments between runs

– Reliable performance, even in demanding environments

It’s engineering that quietly does its job, day in and day out.

🛠 Fine-Tuning Made Easy

Need to adjust the fill volume? UBA pumps make it straightforward. You can tweak the stroke length manually – or digitally, if you’re using a servo-driven model like the E1–E5. That flexibility is a game-changer when you’re switching between products, running small test batches, or working under strict QA protocols.

💨 Power That Doesn’t Flinch

UBA pneumatic pumps run best at around 75–80 psi. But here’s the clever part: even if you slow down the stroke using the built-in needle valves, the pump doesn’t lose its punch. Full air pressure stays behind the piston, so every stroke delivers the same force and volume.

That means you can dial in slower speeds for tricky products or ultra-precise fills—without compromising performance.

🌡 Handles the Tough Stuff

Not all fluids behave nicely. Some are thick, sticky, or just plain awkward. UBA pumps are built to handle the full spectrum – from watery solutions to heavy gels with no drop in accuracy.

Thanks to interchangeable valve designs (check valve or rotary valve) and tight mechanical control, they stay consistent even when the product isn’t. We’ve seen them succeed in:

– Personal care creams and gels

– Viscous food ingredients like syrups and sauces

– Industrial fluids such as adhesives and lubricants

– Pharma-grade applications requiring sterile, precise dosing

– Battery electrolytes, where containment and consistency are critical

If it flows, UBA can handle it.

🔁 Accuracy That Sticks Around

Precision isn’t just about getting it right once – it’s about getting it right every time. UBA pumps are designed for repeatability. Once you’ve dialed in your settings, they hold steady across shifts, operators, and production runs.

That kind of consistency helps you:

– Meet tight fill tolerances

– Minimise rework and product giveaway

– Keep your QA team happy

🧠 Final Thoughts

UBA pumps aren’t just built to fill – they’re built to fill precisely, cycle after cycle. Whether you’re scaling up, launching a new product, or upgrading your line, their design gives you the accuracy edge.

Need help matching a pump model to your fill specs?