Category

UBA Pumps

-

What Makes UBA Pumps So Accurate?

A Look at the Engineering Behind Precision Precision in liquid filling isn’t just about hitting a target – it’s about hitting it every time. Whether you’re working with delicate pharmaceuticals…

-

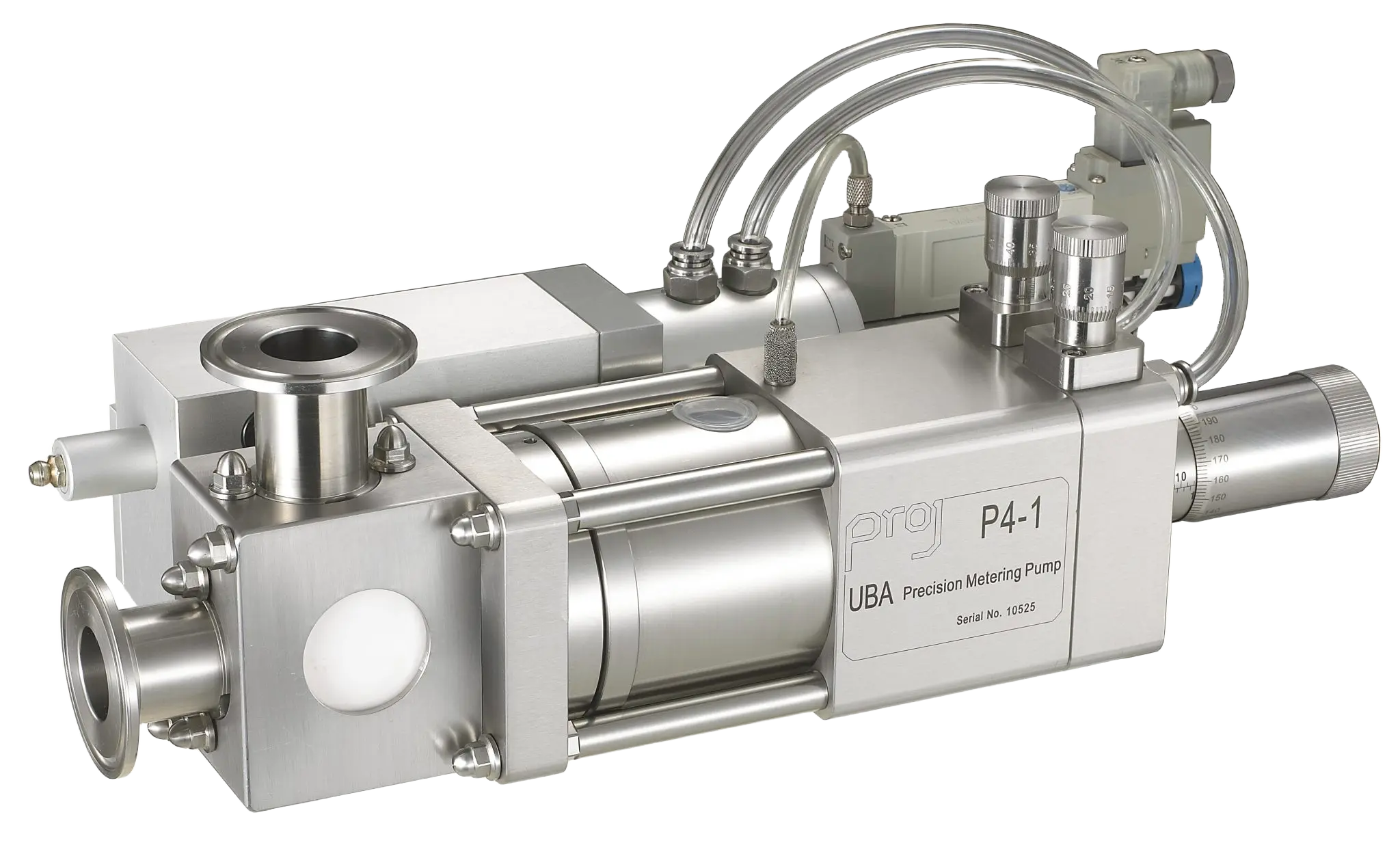

UBA P1–P5 Pneumatic Series Overview

At Hi-Tech Machinery, we know that precision matters, especially when it comes to filling liquids accurately and repeatably. Our UBA P1–P5 pneumatic metering pumps provide a reliable solution for manufacturers…

-

Introduction to UBA Metering Pumps

In industries where accuracy, repeatability, and reliability aren’t just beneficial, but essential, precision dispensing technology can make all the difference. At Hi-Tech Machinery, we specialise in providing liquid filling equipment…

-

Understanding Pump Selection

Check Valve Vs. Rotary Valve with UBA Pumps When choosing a UBA pump for your filling application, the valve configuration is just as important as the pump model. UBA pumps…