UBA metering pumps are trusted for their precision, reliability, and versatility—but with multiple models available, how do you choose the one that best fits your application?

In this post, we’ll break down the P-series pneumatic pumps (P1–P5) and their servo-driven equivalents (E1–E5), helping you understand how each model differs and what makes them suitable for different production needs.

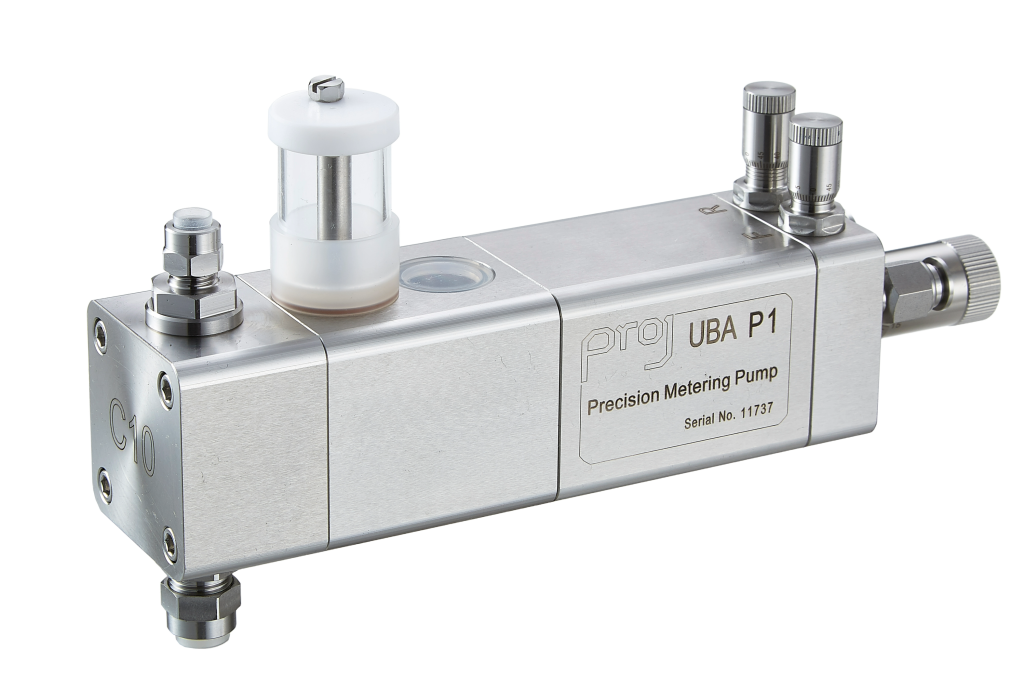

🔹 Pneumatic Models: P1 to P5

The P-series pumps operate pneumatically and are ideal for production environments where air-driven equipment is standard. They offer high repeatability, simple integration, and low maintenance.

| Model | Typical Volume Range | Key Use Cases |

| P1 | Up to ~1 ml | Diagnostic reagents, essential oils, microdosing |

| P2 | 1–10 ml | Serums, pharmaceuticals, inks |

| P3 | 10–50 ml | Lotions, sauces, lubricants |

| P4 | | 50–250 ml | Creams, cleaning products, adhesives |

| P5 | 250–500+ ml | Bulk fills, paint, syrups, high-viscosity products |

*Volume ranges are approximate and depend on stroke settings and valve type.

⚡ Servo-Driven Models: E1 to E5

The E-series pumps use a servo motor to control the piston stroke electronically. This allows for programmable dosing, finer resolution, and greater flexibility—ideal for lines that require automated recipe changes, traceability, or integration with PLC systems.

| Pneumatic Model | Servo Equivalent | Added Benefits |

| P1 | E1 | Ultra-precise microdosing with electronic stroke control |

| P2 | E2 | Ideal for cleanroom and pharma environments |

| P3 | E3 | Ideal for cleanroom and pharma environments |

| P4 | E4 | Programmable for multi-product lines |

| P5 | E5 | High-volume filling with full digital control |

🔁 Pneumatic vs. Servo: Quick Comparison

| Feature | Pneumatic (P Seires) | Servo (E-Series) |

| Drive Type | Air-powered | Electric servo motor |

| Control | Manual or basic control | Fully Programmable |

| Flexibility | Simple setup, manual adjustment | Fast recipe changeover and recipe storage |

| Best For | Stable, high-speed runs | Multi-product, high precision and speeds |

| Maintenance | Minimal mechanical complexity | Slightly higher, but predictable |

🧠 Which UBA Model Is Right for You?

Start by considering:

– Fill volume: Smaller volumes suit P1–P2 or E1–E2

– Automation level: Servo models integrate better with digital control systems

– Product type: Heavier viscosities may require larger models (P4/P5 or E4/E5) and rotary valve setups

– Process goals: Need changeovers or recipe control? Go servo. Running a single product at high speed? Pneumatic could be ideal.

Not sure which model fits best? That’s what we’re here for.

📩 Talk to our technical team – www.fillers.co.uk/contact and we’ll help you find the perfect fit.