Precision dispensing at its core

In industries where accuracy, repeatability, and reliability aren’t just beneficial, but essential, precision dispensing technology can make all the difference. At Hi-Tech Machinery, we specialise in providing liquid filling equipment that meet the highest standards of performance and consistency. One of our flagship product lines is the UBA range of metering pumps, trusted by manufacturers across sectors for their precise, clean, and efficient liquid dispensing. Whether you’re filling pharmaceutical vials, cosmetic containers, food sauce sachets or chemical products, UBA pumps are designed to deliver exceptional results—time after time.

🛠 What Are UBA Metering Pumps?

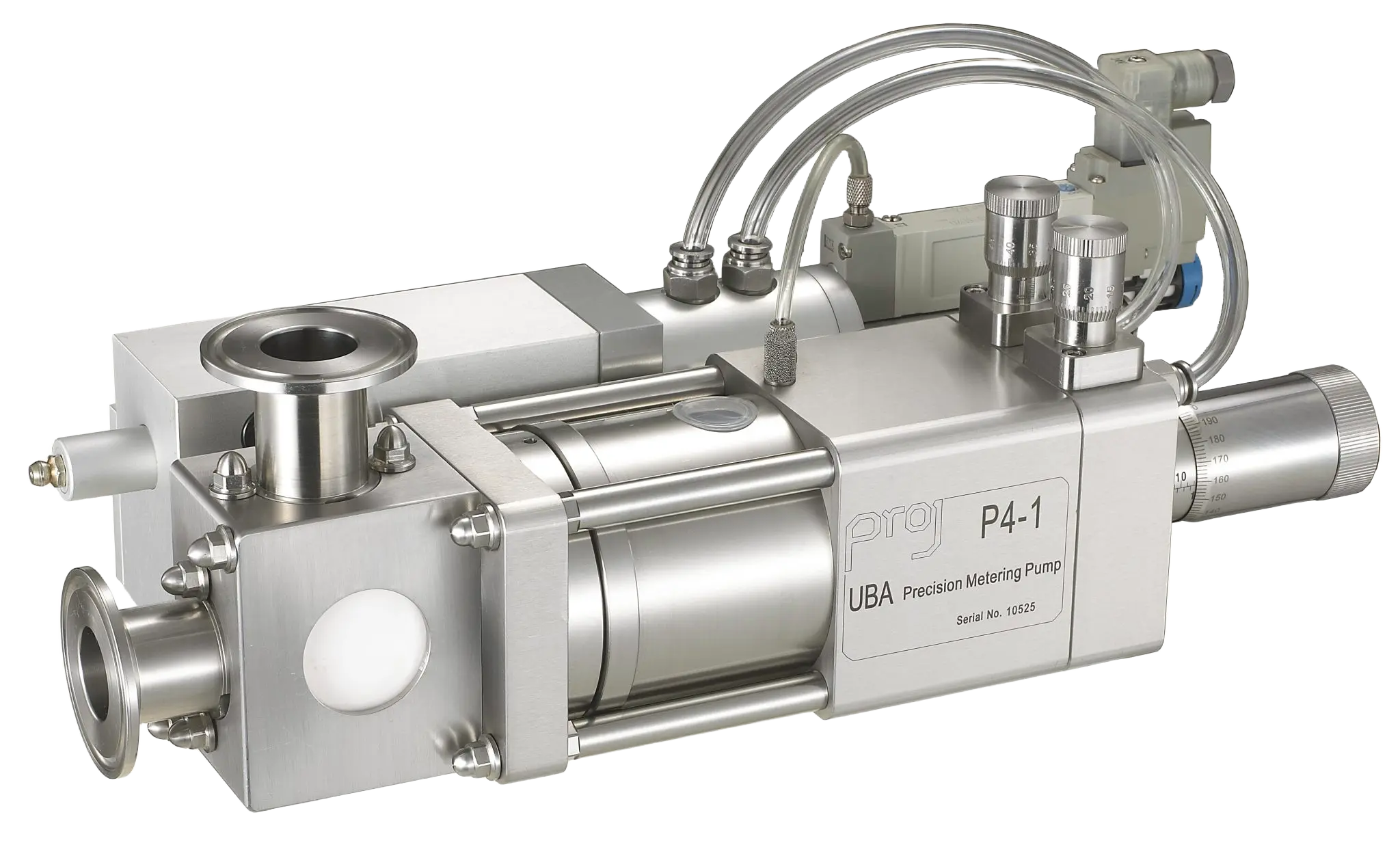

UBA metering pumps are volumetric piston filling systems engineered for high-accuracy liquid filling. They are available in both pneumatic and servo-driven variants and come in a series of five models (P1 through P5) to suit a wide range of applications. What sets them apart is not just their precision, but their modular, hygienic design, which makes them ideal for everything from small-scale lab use to high-speed production lines.

💡 Designed for Versatility: Pneumatic and Servo Options

- Pneumatic UBA Pumps offer a cost-effective, reliable solution for semi-automatic or fully automated lines where consistent air supply is available.

- Servo-Driven UBA Pumps provide more precise control, smoother dispensing, and greater flexibility in adjusting fill parameters—perfect for complex or variable products.

Both options deliver repeatable results, but servo systems often excel in environments requiring tighter control and traceability.

🔄 Valve Types: Check Valve vs. Rotary Valve

Not all fluids behave the same, which is why UBA pumps are available in two distinct valve configurations:

Check Valve Pumps

Ideal for low- to medium-viscosity liquids (up to ~20,000 centipoise) with no particulates. These are commonly used in pharmaceuticals, cosmetics, and food-grade applications.

Rotary Valve Pumps

Designed for higher-viscosity fluids and those containing soft or suspended particulates (>20,000 cps), such as sauces, gels, creams, or chemical slurries.

This versatility makes UBA pumps a popular choice across industries, capable of handling everything from water-like fluids to viscous pastes.

📏 Accuracy Where It Matters

UBA pumps are engineered to deliver exceptional volumetric accuracy, often achieving repeatability within ±0.5%. This level of precision is critical for companies focused on product integrity, regulatory compliance, and minimising waste.

⚙️ Built for Performance and Longevity

Each pump is constructed with robust, corrosion-resistant materials and designed for easy maintenance and cleaning. This results in lower downtime, longer pump life, and reduced total cost of ownership.

🚀 Ready to Scale with Your Production

Whether you’re scaling up production, automating for the first time, or refining an existing filling line, UBA pumps provide a scalable, reliable solution. With modular design and a wide range of configurations, they can grow alongside your business needs.

📣 Stay Tuned

In upcoming posts, we’ll explore the differences between each UBA series, help you choose between pneumatic vs. servo, and take a closer look at common applications and best practices for maintenance. Whether you’re a plant manager, technician, or engineer, there’s something here for you.