Check Valve Vs. Rotary Valve with UBA Pumps

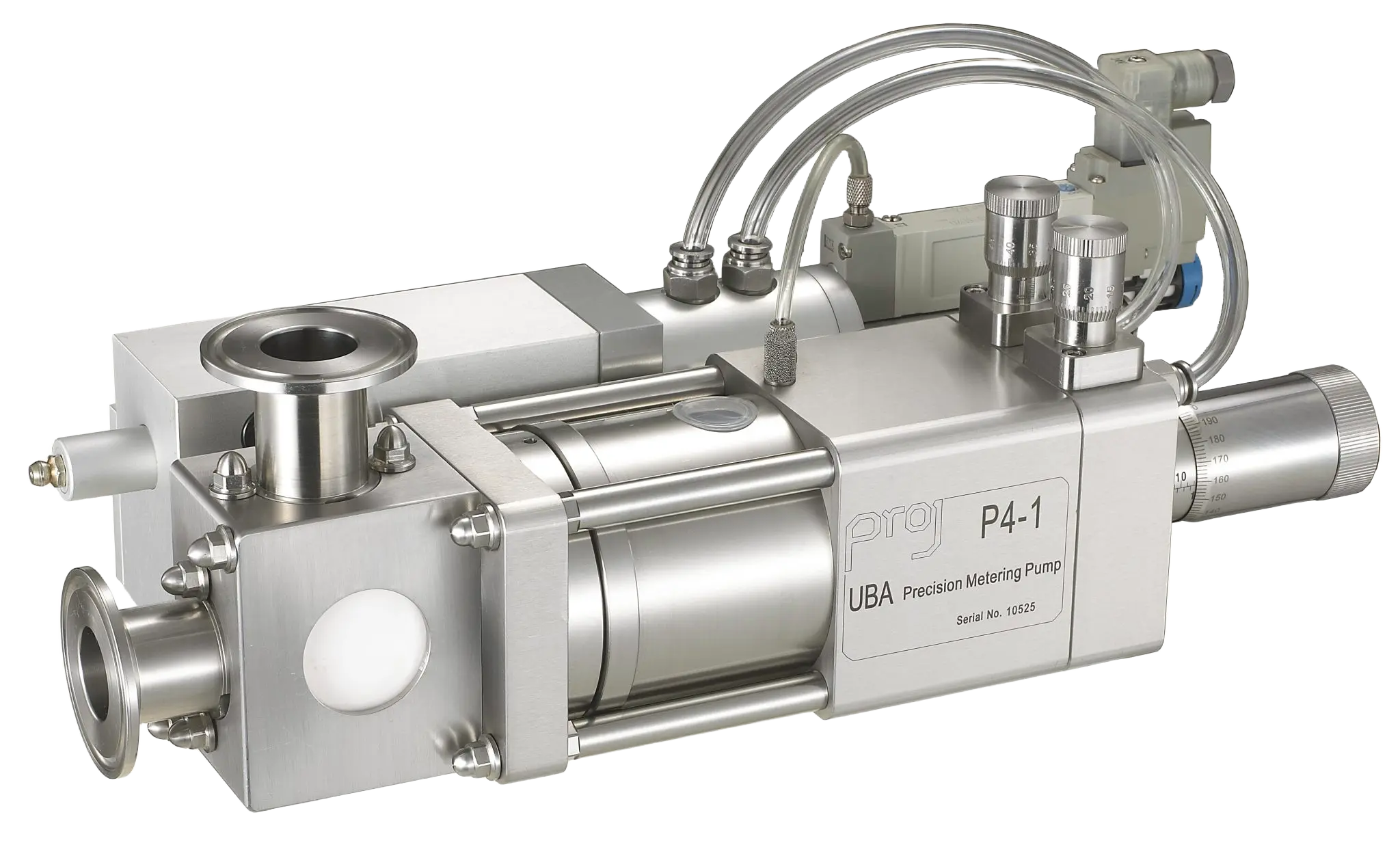

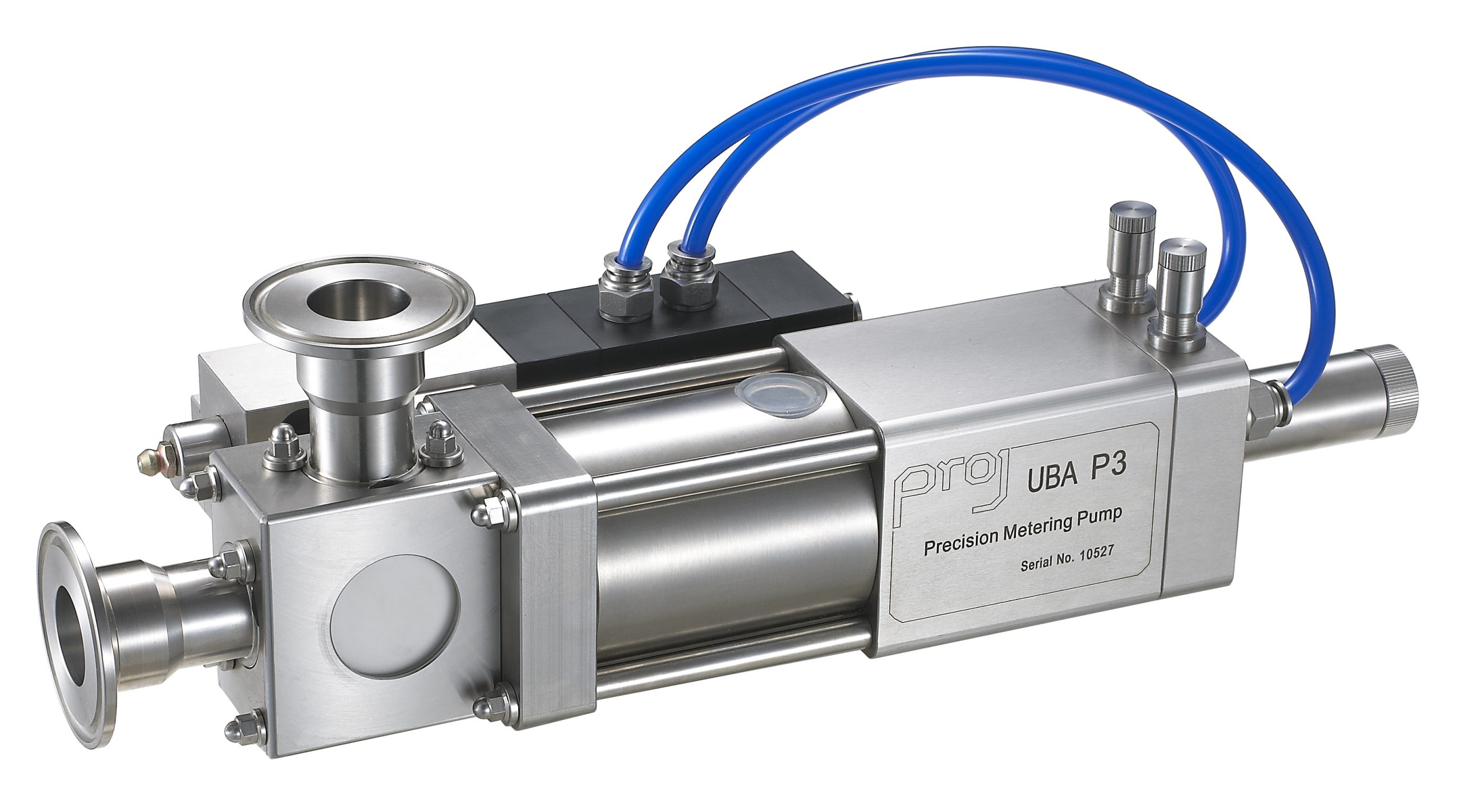

When choosing a UBA pump for your filling application, the valve configuration is just as important as the pump model. UBA pumps can be supplied with either dual check valves or a single rotary valve, and selecting the right one can significantly impact performance, reliability, and product quality.

In this post, we’ll break down the differences, applications, and considerations when deciding between check valve and rotary valve UBA pump configurations.

🔄 Check Valve: For Clean, Low-Viscosity Fluids

Best for:

✔ Fluids up to 20,000 cps

✔ Clean products without suspended particles

✔ Thin to moderately viscous liquids

How it works:

Check valves use spring-loaded poppets to allow flow in one direction and prevent backflow. They are ideal for precise dosing of free-flowing products where clogging or shear is not a concern.

Typical applications:

- Medical reagents

- Perfumes and fragrances

- Food sauces

- Water-thin cosmetics or serums

Why choose it?

✅ High speed and precision for clean fills

✅ Lower maintenance compared to rotary valves

✅ Compact and cost-effective solution

🔁 Rotary Valve: For Viscous or Particulate-Rich Products

Best for:

✔ Viscosities above 20,000 cps (like gels or pastes)

✔ Products with suspended solids or particulates

✔ Shear-sensitive or sticky materials

How it works:

Rotary valves use a rotating port to align inlet and outlet paths at different phases of the pump cycle. This design allows thicker fluids and particulates to pass through without clogging or compromising accuracy.

Typical applications

- Lotions with particulates

- Creamy sauces

- Industrial greases

- Suspensions or emulsions

Why choose it?

✅ Handles thick or challenging fluids with ease

✅ More robust for long production runs

✅ Reduces shear stress on sensitive products

⚖️ Quick Comparison

| Feature | Check Valve | Rotary Valve |

| Max Viscosity | Up to 20,000 cps | Over 20,000 cps |

| Particulates | Not recommended | Ideal for suspended solids |

| Maintenance | Simple, fewer moving parts | More components, regular checks needed |

| Flow Type | Free-flowing, clean liquids | Thick, sticky, shear-sensitive fluids |

| Speed & Repeatability | High (with correct setup) | High (with correct setup) |

🧠 Final Thoughts: Which One Is Right for You?

If you’re filling clear, low-viscosity products, go with the check valve version for simplicity and speed. For viscous, textured, or products with particulates, the rotary valve setup is your go-to.

Still unsure? Our team can help you evaluate your product, production goals, and operational environment to guide you toward the ideal pump and valve configuration.

📩 [Reach out here] and we’ll walk you through your options.